|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7xjf2e5pr Production Operation Management: Key Concepts and StrategiesProduction operation management is a critical component in the efficient functioning of any manufacturing or service industry. It involves planning, organizing, directing, and controlling all aspects of production to ensure the effective transformation of resources into finished goods or services. Understanding Production Operation ManagementProduction operation management encompasses a range of activities designed to optimize production processes. It ensures that the operations within a production facility are efficient and effective. Core Objectives

Key FunctionsThe primary functions of production operation management include:

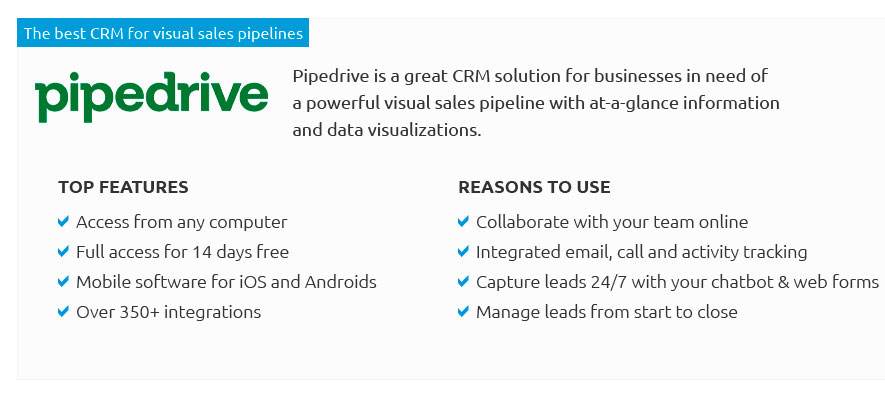

Strategies for Effective Production Operation ManagementImplementing effective strategies is crucial for optimizing production operations. Here are some key strategies: Lean ManufacturingLean manufacturing focuses on minimizing waste without sacrificing productivity. This strategy is vital for maintaining efficiency and reducing costs. Six SigmaSix Sigma is a data-driven approach aimed at improving quality by identifying and removing defects in production processes. To learn more about integrating customer relationship management with production, explore this best crm for online business resource. Technology in Production Operation ManagementTechnology plays a pivotal role in modern production operation management. Automation and advanced software tools are transforming how operations are managed. AutomationAutomation reduces human error and increases efficiency in repetitive tasks. Robots and automated systems are now commonplace in production facilities. Software SolutionsAdvanced software solutions assist in planning, scheduling, and managing inventory. For businesses looking to integrate CRM solutions, consider exploring crm ecommerce options. FAQsWhat is the role of inventory management in production operation management?Inventory management ensures that the necessary materials are available for production while minimizing costs associated with excess inventory. It balances supply with demand to prevent both shortages and overstock. How does quality control fit into production operation management?Quality control is integral to maintaining standards and ensuring that products meet customer expectations. It involves regular inspections and testing during the production process to catch defects early. Why is lean manufacturing important?Lean manufacturing is important because it focuses on reducing waste and improving efficiency, which can lead to significant cost savings and better use of resources. https://www.inboundlogistics.com/articles/operations-management-vs-production-management/

Operations management involves strategic planning, forecasting, process design, and quality management. Production management focuses on ... https://www.mbacrystalball.com/blog/operations-management/

Production / Operations Management is defined as the process which transforms the inputs/resources of an organization into final goods (or services) through a ... https://journals.sagepub.com/home/PAO

Listen to the editors. In a recent interview with Listen to the Editors, Drs. Kalyan Singhal and Subodha Kumar discuss POM's review process and how to integrate ...

|